Bellows Seal Valve Automation and Control Systems for Industrial Operations

Bellows seal valves play a critical role in various industrial operations, providing reliable, leak-tight performance in demanding environments. With the integration of automation and control systems, these valves have become more efficient, reliable, and easier to manage. This article explores the benefits, components, and future trends of bellows seal valve automation in industrial settings.

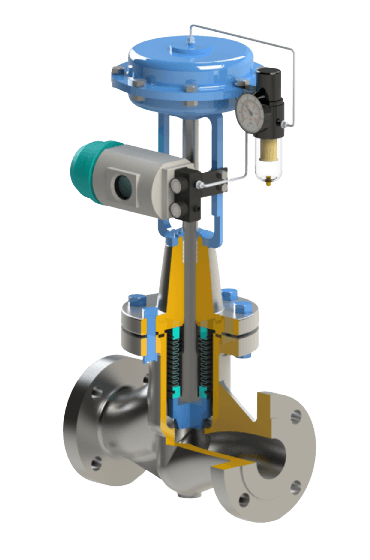

Understanding Bellows Seal Valves

Bellows seal valves are designed to provide a hermetic seal, preventing any fluid or gas from escaping. They are commonly used in industries where leakage of hazardous or toxic substances must be avoided, such as in chemical processing, oil and gas, and power generation. The key component of these valves is the flexible metal bellows, which is welded to the valve stem and body. This design ensures a leak-proof seal, even as the valve opens and closes.

The Role of Automation in Industrial Valves

Valve automation involves using various technologies to control the operation of valves without manual intervention. This includes actuators, positioners, and controllers that work together to ensure precise and reliable valve performance. Automation enhances operational efficiency, safety, and reliability, making it an invaluable investment for industrial operations.

Components of Bellows Seal Valve Automation Systems

Actuators

Actuators are devices that convert control signals into mechanical movement, allowing the valve to open or close. In the context of bellows seal valves, actuators are essential for automating the valve's operations.

Pneumatic Actuators: These use compressed air to generate movement. They are known for their reliability and quick response times, making them ideal for applications requiring fast operation.

Electric Actuators: These use electrical energy to drive the valve stem. They offer precise control and are suitable for applications where accuracy is critical.

Hydraulic Actuators: These use pressurized fluid to produce movement. They are typically used in applications requiring high force and are known for their robustness.

Positioners

Positioners ensure that the valve reaches the exact position as dictated by the control signal. They adjust the actuator's output to correct any deviations from the desired position. There are two main types of positioners: pneumatic and digital. Pneumatic positioners use air pressure for adjustments, while digital positioners use electronic signals for more precise control.

Controllers

Controllers process input signals and generate output signals to drive the actuators. They are the brains of the automation system, ensuring that the valve operates according to the specified parameters.

Control Systems for Bellows Seal Valves

Control systems integrate various components like actuators, positioners, and controllers to automate valve operations. These systems can be linked to a central control system, allowing for remote monitoring and control of the valves. Integration with industrial automation systems enables seamless operation, real-time monitoring, and data collection for predictive maintenance and optimization.

Advantages of Automating Bellows Seal Valves

Enhanced Precision and Control

Automation allows for precise control over valve operations, ensuring optimal performance and reducing the risk of errors. This precision is particularly important in processes where even small deviations can lead to significant issues.

Increased Safety and Reliability

Automated valves reduce the need for manual intervention, minimizing the risk of human error and enhancing overall safety. This is especially critical in industries handling hazardous substances, where leaks can have catastrophic consequences.

Improved Efficiency and Productivity

Automation streamlines operations, leading to increased productivity and efficiency. Automated systems can operate continuously without the need for manual adjustments, reducing downtime and ensuring consistent performance.

Challenges in Valve Automation

Technical Challenges

Implementing automation in bellows seal valves can present several technical challenges. These include ensuring compatibility between different components, maintaining precise control in complex systems, and addressing issues related to signal interference and data accuracy.

Cost Considerations

While the long-term benefits of automation are significant, the initial investment can be substantial. Industries need to consider the costs of purchasing and installing automation systems, as well as potential expenses for training personnel and maintaining the systems.

The future of valve automation lies in the integration of smart technologies and the Internet of Things (IoT). Smart valves equipped with sensors can provide real-time data on their status and performance, enabling predictive maintenance and reducing the risk of unexpected failures.

Predictive Maintenance

Predictive maintenance uses data collected from sensors to predict when a valve is likely to fail or require maintenance. This approach allows for timely interventions, reducing downtime and maintenance costs. As data analytics and machine learning technologies advance, predictive maintenance will become even more accurate and effective.

Selecting the Right Automation System

When selecting an automation system for bellows seal valves, it is essential to consider factors such as the specific requirements of the application, the operating environment, and the available budget. Customization options should also be explored to ensure that the system meets all operational needs. Consulting with experts and conducting thorough evaluations can help in choosing the right system.

Maintenance of Automated Bellows Seal Valves

Routine maintenance is crucial to ensure the longevity and optimal performance of automated bellows seal valves. This includes regular inspections, cleaning, lubrication, and calibration of components. Troubleshooting common issues, such as signal loss or actuator malfunctions, should be part of the maintenance protocol.

Environmental Impact of Automated Valve Systems

Automating bellows seal valves can have a positive environmental impact. By ensuring leak-free operations, these systems reduce emissions of hazardous substances, contributing to environmental protection. Additionally, the enhanced efficiency of automated systems can lead to reduced energy consumption, further supporting sustainability efforts.

FAQs

What is the primary benefit of automating bellows seal valves?

The primary benefit is enhanced precision and control, which leads to improved operational efficiency and safety.

How does automation enhance valve performance?

Automation enhances performance by providing precise control, reducing human error, and allowing for continuous, consistent operation.

What are the most common types of actuators used?

The most common types of actuators are pneumatic, electric, and hydraulic actuators.

Are automated valve systems environmentally friendly?

Yes, they help reduce emissions by ensuring leak-free operations and can also improve energy efficiency.

What should be considered when choosing an automation system?

Factors to consider include the specific application requirements, operating environment, budget, and potential for customization. Consulting with experts and conducting thorough evaluations are also crucial steps.

Conclusion

In conclusion, the automation and control of Bellow sealed Globe Pneumatic Actuator Control valves represent a significant advancement in industrial operations. By integrating advanced technologies, these systems enhance precision, safety, and efficiency, offering substantial long-term benefits despite the initial investment costs. As industries continue to evolve, the adoption of smart valves and predictive maintenance practices will further optimize performance and sustainability.